Diaphragm jigs are divided into two forms: left type and right type jigging surfaces. The diaphragm jig is a fixed and immovable die. It is applicable to the separation of metallic materials such as iron ore, such as tungsten bearing placer, tin ore, etc. It can be used to select both fine sand raw materials and coarse raw materials. The larger feed size distribution is 6-8 mm, but in some cases, the larger size distribution is 12 mm.

The LTS300450 upward moving diaphragm jigging mechanism is composed of key components such as the overall body, transmission system, underfloor heating water separator, diaphragm, and valve. The human body has two sizes of jigging buckets, and each diaphragm bucket is divided into two parts: the jigging area and the diaphragm area using different baffles. The entire process of jigging is carried out by the agitation of substances (water) caused by the repeated left and right movements of the vulcanized rubber diaphragm. The motor drives the large leather pulley to rotate according to the triangular belt, causing the crankshaft on the camshaft to move left and right for fitness. The connecting crank arm with this crankshaft also moves up for fitness. There are also two crankshafts on the crank arm that are connected to a vulcanized rubber diaphragm, thereby causing the diaphragm to repeatedly move left and right for jigging.

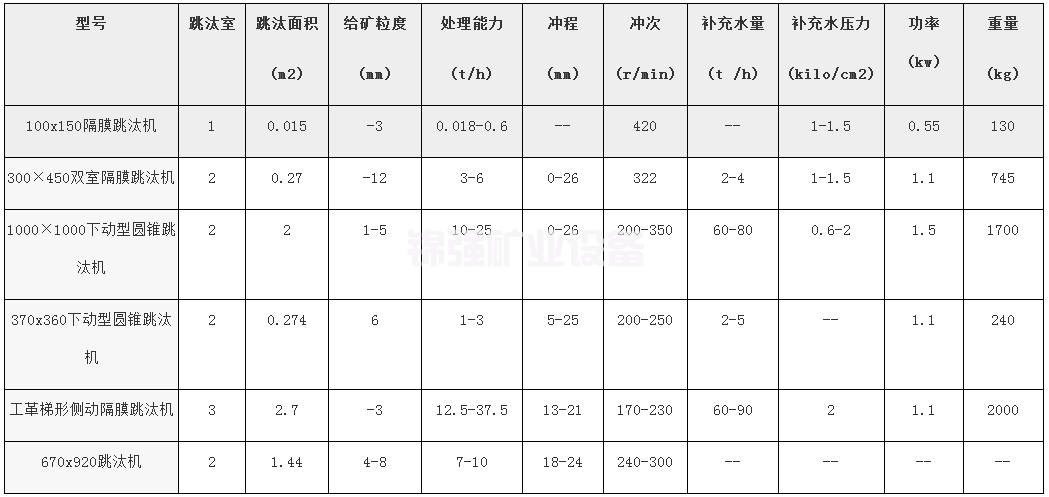

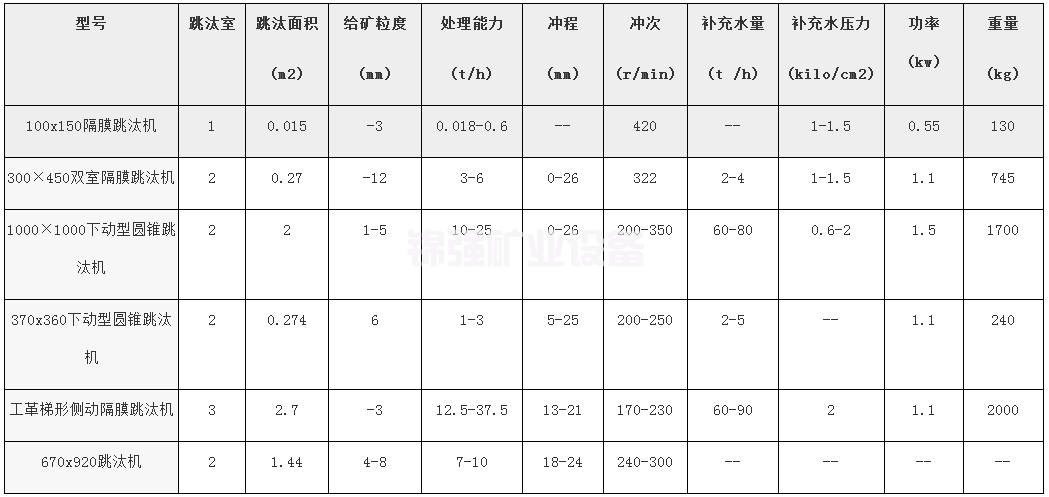

According to the particle size distribution of the iron ore to be solved, the upward moving diaphragm jig can change the stroke of the crankshaft and select different four strokes, so as to obtain the best practical effect of jigging. The way to change the punching frequency is to replace the small belt pulley, which can be divided into two types: 322 times per minute; 420 times/minute. The four stroke method selected includes loosening the fixed screws and screw caps, pulling out the positioning pin, and rotating the relative position between the axial force adjustment sleeve and the camshaft. There are 11 different four stroke options (0-25.3 millimeters)

Since a die is added to the top of the sieve during operation, the upward moving diaphragm jig can be used to solve the problem of raw materials with uneven particle size distribution. (Note: This screen is not provided according to the ordering regulations.) After the selected raw ore is sent to the jigging chamber, due to the stirring effect of the diaphragm, the ore particles are proportionally layered in the material; Fine and heavy ore particles settle in the ore storage of the jig bucket according to the gaps in the human bed particles and the circular hole sieve. The coarse and light ore particles (minerals) on the top layer are rushed towards the discharge port at the tail end of the dice by material flow. Because the rear jig chamber is 50 millimeters lower than the front jig chamber, the light ore particles overflow through the tail plate of the pre-treatment chamber and enter the rear chamber, where they are once again subjected to jigging. The number of tail plate positions must be adjustable to control the size of ore discharge. The titanium concentrate in the storage hopper is discharged from the ore discharge pipe on time.

The upward moving diaphragm jig is used to separate minerals such as gold, tin, tungsten, titanium, hematite, copper, coal, etc., and has been widely used in the manganese ore beneficiation plant industry.

Diaphragm jigs are divided into two forms: left type and right type jigging surfaces. The diaphragm jig is a fixed and immovable die. It is applicable to the separation of metallic materials such as i

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents.

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents. The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China.

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.