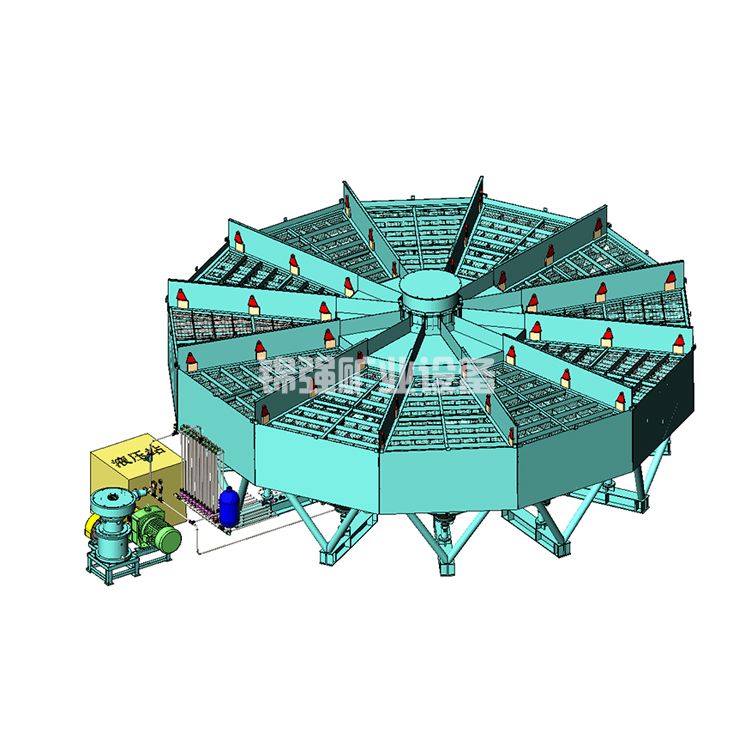

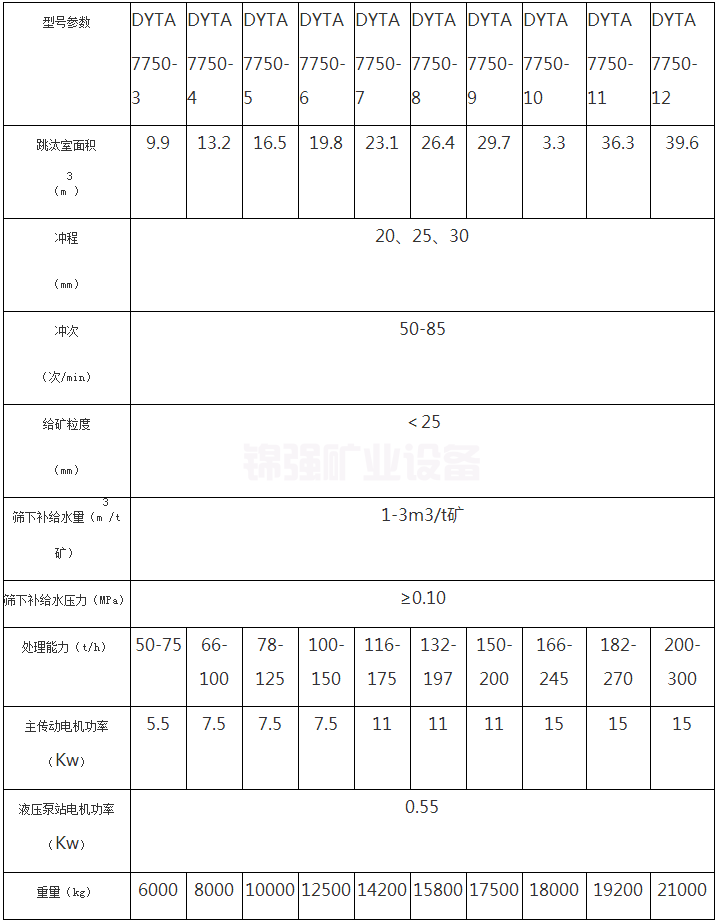

Hydraulic jigs are formed by the development trend of circular jigs, which are mainly composed of two parts: pushing and acid washing tanks: pushing is a mechanical equipment hydraulic press method, and the driving force of hydraulic jigs is provided by an electric motor. According to the speed regulation organization, the output shaft of the reducer drives the camshaft to rotate, and the camshaft promotes the regular and repeated movement of the plunger pump of each main hydraulic cylinder, Furthermore, electromagnetic energy is converted into mechanical kinetic energy and then into hydraulic functions. The hydraulic jigging machine uses hydraulic oil pipes and various valves to drive the driven hydraulic cylinder for fitness activities, thereby driving the left and right pulsating drinks of the jigging machine's cone bucket. The DYTA-7750 hydraulic radial jig uses an electromagnetic induction variable speed asynchronous motor to complete the adjustment of the stroke, belonging to the range of zero to 90 strokes per minute for infinite adjustment.

Compared with various jigs currently used in mineral processing plants in China, the DYTA-7750 hydraulic radial jig has many advantages: large total area of jigs and strong ability to solve work; Because the jig pickling tank is fan shaped, it is beneficial for purchasing fine grade raw materials; Compact structure, centralized feeding, small indoor space for ore separation, suitable for application in mining vessels; Because the hydraulic transmission system is selected, the transmission mechanism is simplified and the driving force is saved. The total output power of a nine room DYTA-7750 jig is 11.6Kw, which saves about 55% of the driving force compared to a typical jig with the same total area of a beneficiation plant. The jigging curve of the axial hydraulic dynamic sieve jig is similar to a serrated pulsating beverage curve, which is not only conducive to the acquisition of fine sand and heavy mineral substances, but also greatly reduces the water supply flow under the sieve of the jig. The water supply flow under the sieve is about a quarter of that of a typical jig.

At present, foreign hydraulic radial jigs have been widely used in mining ships as roughing machines and equipment to separate placer gold, tin, diamond, tungsten, manganese, Hematite and other iron ores. After many years of practical experience, it has been proven that the hydraulic radial jig beneficiation plant has excellent actual results.

Advantages and characteristics of hydraulic jigs

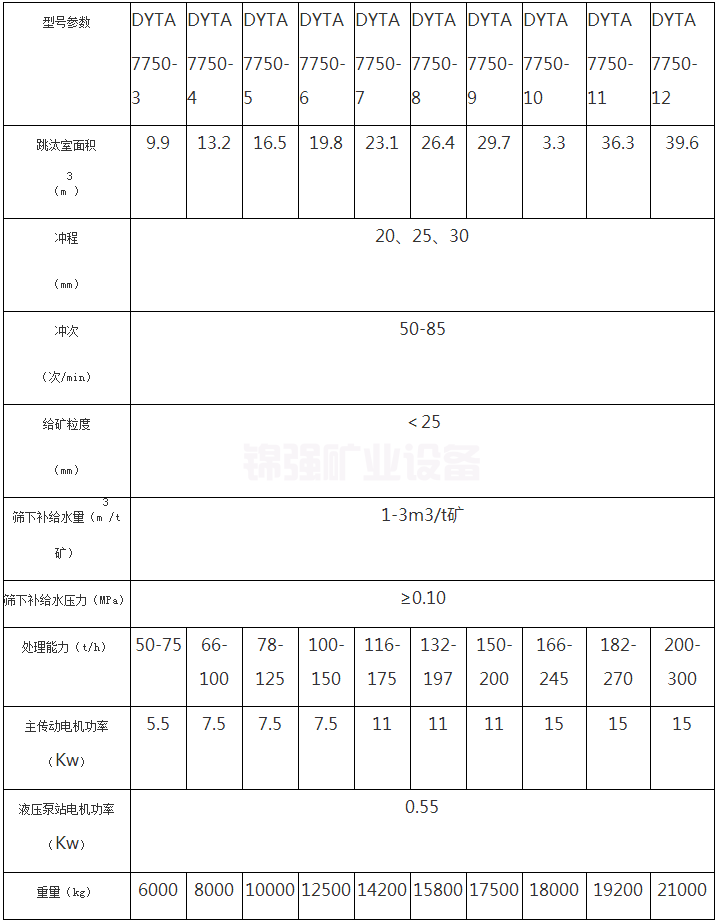

1、 Large working capacity, small land occupation and wide coverage of sorting granularity distribution

2、 High aggregation ratio and high utilization

3、 Easy to install, easy to operate, and easy to maintain

4、 The zigzag wave jig pulsating beverage curve makes it easier for heavy mineral substances to move downwards

5、 Save 60-70% water and 55% electricity compared to traditional jigs

6、 Choose an electromagnetic adjustable speed motor

7、 The hydraulic radial jig is suitable for separating gold, tin, diamond, tungsten, manganese, Hematite and other minerals, especially in the manganese ore, barite powder concentrator industry

Hydraulic jigs are formed by the development trend of circular jigs, which are mainly composed of two parts: pushing and acid washing tanks: pushing is a mechanical equipment hydraulic press method, a

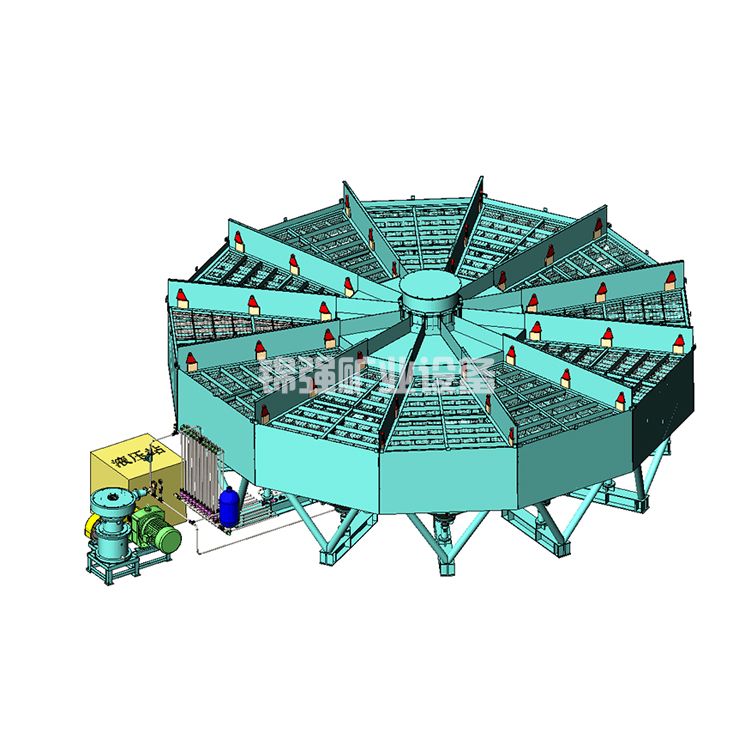

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents.

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents. The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China.

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.