The Rotary Scrubber equipment is commonly used for various difficult to wash block iron ores, and there are two types of Rotary Scrubbers: drum type and drum plus screening strip type. The cylindrical ore washing machine can divide the washed raw materials into+40mm and -40mm secondary commodities, and the -40mm internal double spiral structure trough type sand washing machine can further clean the raw materials into+2mm and -2mm secondary commodities. The ore washing efficiency can reach up to 98%, which is the most effective method for difficult to wash iron ore.

The large cylindrical ore washing machine consists of. The cylinder section is composed of a pulping section and a screening section, and the cylinder body is made of wear-resistant rubber as a jaw.

The basic principle of a large cylindrical ore washing machine: the cleaning cylinder section is supported by four towing wheels, the electric motor drives the reducer, and the size transmission gear drives the cleaning cylinder section to rotate at low speed. Iron ore with mud and lime powder is fed from the feeding port and enters the rotating drum. It is cleaned by installing a wear-resistant rubber lining plate with a certain angle of view inside the drum, which continuously drives the throwing down. The entire process is moved several times from the feeding end to the feeding end, and is washed and rinsed in both directions or reverse directions. The clean iron ore is lifted by a large Rotary Scrubber and unloaded into two layers of conical screens, which are divided into coarse, medium, and coarse The three fine particle size distributions are discharged respectively. Sewage with sludge is discharged according to the perforated partition at the feeding or feeding end.

Advantages and characteristics of large cylindrical ore washing machines

1. High processing capacity and strong ore washing ability;

The

2.long shaped ore washing cylinder ensures a long residence time for the material inside, fully and effectively dispersing the material;

3. The cylinder is made of thickened steel plates;

4. Use heavy-duty bearings, gears, and rollers;

5 high-power motors and gear systems generate efficient torque;

6. Flush the inner wall of the cylinder with high-pressure flushing water;

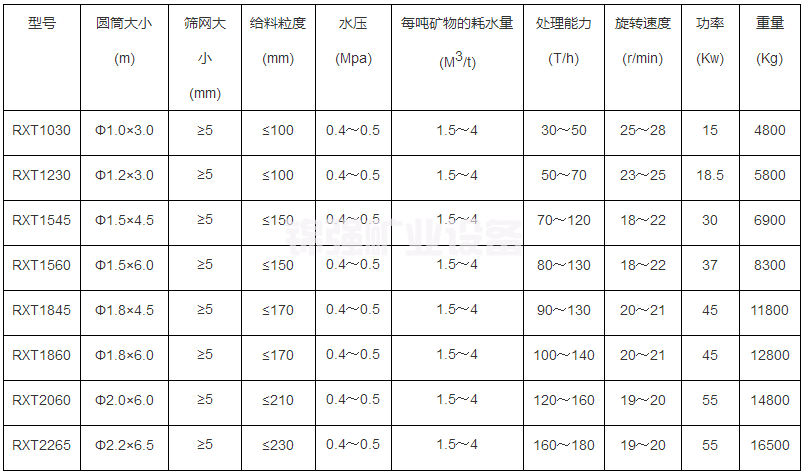

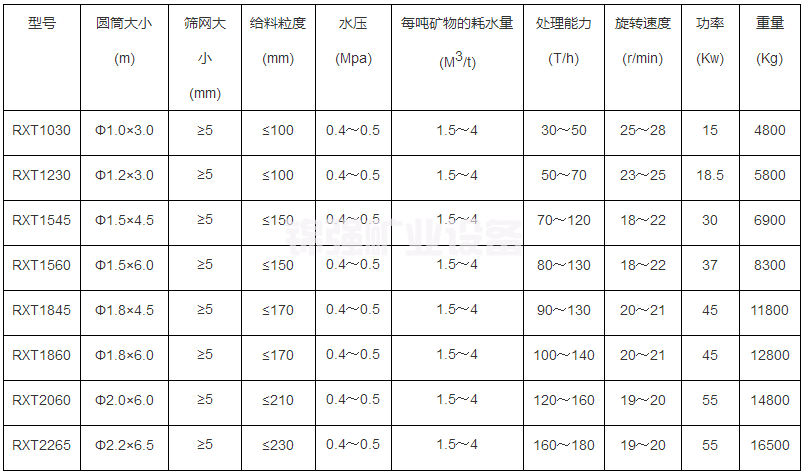

7.The maximum feed particle size can reach 230mm.

The Rotary Scrubber equipment is commonly used for various difficult to wash block iron ores, and there are two types of Rotary Scrubbers: drum type and drum plus screening strip type. The cylindrical

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents.

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents. The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China.

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.