Main uses of permanent magnet magnetic separators: Permanent magnet magnetic separators are commonly used for rough selection and optimization of rare metals, non-metallic materials, and light ink metal materials in dry magnetic separators. The principle of a permanent magnet magnetic separator is to use the difference in the specific magnetization index size of minerals themselves to complete the screening of magnetic and non magnetic minerals.

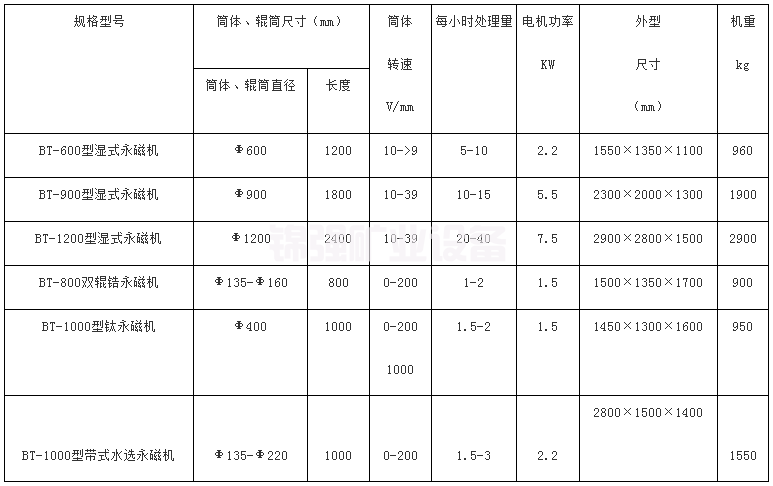

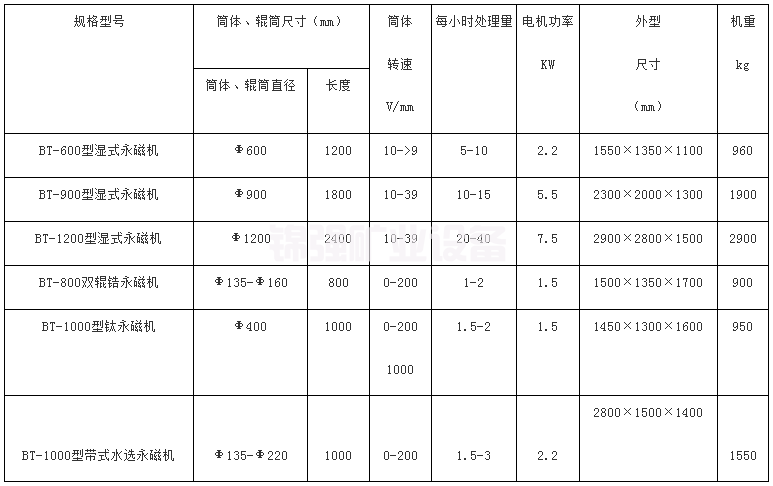

The BT series of permanent magnetic separators are rare earth permanent magnetic disk type and roller type dry magnetic separators. The magnetic source is made of Ferrite core and rare earth plastic anti-static tweezers. According to different job responsibilities, rare earth permanent magnet disc machines can be divided into two types: dry and wet testing, and dry testing machines can be further divided into three types: disc, roller, and composite. Dry test disc type machine, the upper cylinder (small cylinder) is weak magnetic type, which is generally used to remove magnetic minerals with strong conduction zone, such as Hematite, magnetic Metalloid, etc. The lower cylinder (large cylinder) has high magnetization, which is generally used for commercial selection of Ilmenite, copper, etc., and the output depends on the diameter and length of the cylinder section; Dry test roller machine, generally divided into two rollers, with a length of between 600 and 1500Mm and a diameter of Φ In the range of 130-220Mm, the maximum magnetization strength at present can reach 22000 oz, which is crucial for optimizing zircon, gold red, etc; Composite type, with two to three types of upper and lower rollers and two to three types of upper and lower rollers. The wet test models are divided into three types: wet test downstream, wet test backflow and wet test semi backflow. The size and length of pickling tank and cylinder section are determined according to the production capacity, and the magnetization is also determined according to the type of necessary elements, which are commonly preferred for manganese ore, copper ore and Hematite; The continuous rare earth permanent magnet machine with wet test roller is mainly used for iron removal, roughing and optimization of mining enterprises such as Wolframite, titanium ore and Limonite. Its characteristics are good selectivity, large production capacity and easy maintenance.

Permanent magnetic drum magnetic separators and dry permanent magnetic separators are suitable for iron removal of non-metallic raw materials such as powdered titanium ore, manganese ore, Chromite, purple ivory, etc. The permanent magnet cylindrical magnetic separator and dry permanent magnet magnetic separator have the characteristics of light model, strong magnetism, low energy consumption, stable characteristics, and wide application range.

Φ 400, length 1000-1500mm. Work capacity per hour: 1-4 tons

Φ 500, length 1000-1500 mm. Work capacity per hour: 2-6 tons

Main uses of permanent magnet magnetic separators: Permanent magnet magnetic separators are commonly used for rough selection and optimization of rare metals, non-metallic materials, and light ink met

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents.

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents. The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China.

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.