Vanadium titanium alloy, as an important metal material, has a wide range of applications in various fields, such as aviation, aerospace, electronics, machinery and other industries. However, the production process of vanadium titanium alloy generates a large amount of waste residue and wastewater, causing serious environmental pollution. In order to solve this problem, vanadium titanium gravity separation technology has emerged.

1、 Concept of vanadium titanium gravity separation technology

The vanadium titanium gravity separation technology refers to the physical or chemical treatment of vanadium titanium waste residue and wastewater, which separates and recovers useful elements, achieving the goal of resource utilization. This technology can effectively reduce the discharge of vanadium titanium slag and wastewater, reduce environmental pollution, and also improve the recovery rate and product quality of vanadium titanium alloy.

2、 Operating Steps of Vanadium Titanium Gravity Separation Technology

1. Treatment of vanadium titanium waste residue

Vanadium titanium waste residue is mainly produced from Ilmenite, vanadium titanium Magnetite and other ores after refining. Vanadium titanium waste residue contains a large number of useful elements such as titanium, iron, vanadium, etc., as well as a large amount of impurities such as silicon, aluminum, magnesium, etc. Therefore, the treatment of vanadium titanium waste residue is the first step of vanadium titanium gravity separation technology.

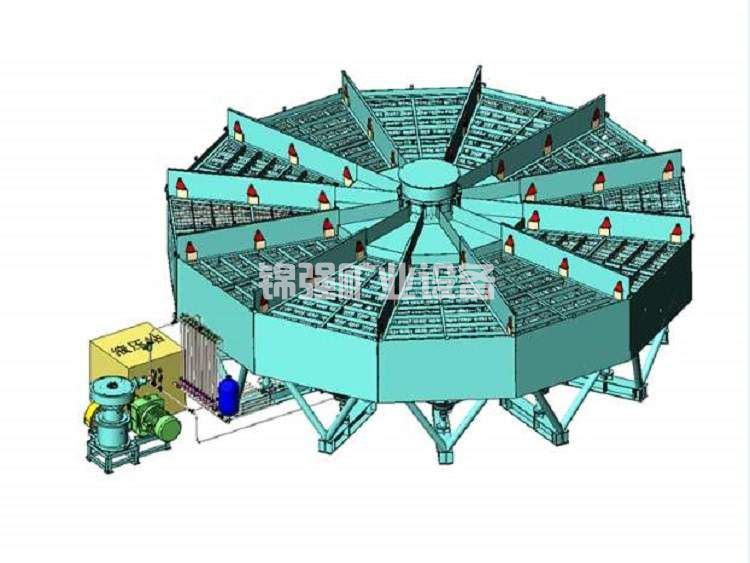

There are two main methods for treating vanadium titanium waste residue, namely physical and chemical methods. Physical methods include gravity beneficiation, magnetic separation, flotation, etc; Chemical methods include leaching, extraction, precipitation, etc. The specific treatment method needs to be selected based on the composition and properties of vanadium titanium waste residue.

2. Wastewater treatment

2. Wastewater treatment

During the production of vanadium and titanium, wastewater contains a large amount of harmful substances such as organic matter, inorganic salts, and heavy metals, causing serious environmental pollution. Therefore, the treatment of wastewater is also an important part of vanadium titanium gravity separation technology.

The treatment methods for wastewater mainly include biological, chemical, and physical methods. Among them, biological method refers to the method of utilizing organisms to degrade and transform organic matter; Chemical method refers to the method of using chemical reactions to convert harmful substances into harmless substances; Physical method refers to the method of separating and filtering wastewater using physical principles. The specific treatment method needs to be selected based on the composition and properties of the wastewater.

Application of vanadium titanium gravity separation technology

The vanadium titanium gravity separation technology has important application value in the production of vanadium titanium alloys. By treating vanadium titanium waste residue and wastewater, the dual goals of resource utilization and environmental protection can be achieved. At the same time, vanadium titanium gravity separation technology can also improve the recovery rate and product quality of vanadium titanium alloy, reduce production costs, and increase economic benefits.

In addition to its application in the production of vanadium titanium alloys, vanadium titanium gravity separation technology can also be applied in other fields, such as metallurgy, chemical engineering, environmental protection, and other industries. With the continuous improvement of environmental awareness and the increasing scarcity of resources, the application prospects of vanadium titanium gravity separation technology will be even broader.

4、 Conclusion

Vanadium titanium gravity separation technology is a significant technology that can achieve the dual goals of resource utilization and environmental protection. By treating vanadium titanium slag and wastewater, the recovery rate and product quality of vanadium titanium alloy can be improved, production costs can be reduced, and economic benefits can be increased. At the same time, vanadium titanium gravity separation technology can also be applied in other fields, with broad application prospects.