Titanium placer is an important ore mainly used for the production of titanium metals and titanium alloys. The beneficiation method of titanium sand ore refers to the process of separating useful minerals and impurities from titanium sand ore. This article will introduce the beneficiation methods of titanium sand ore, including physical beneficiation, chemical beneficiation, and comprehensive beneficiation.

1、 Physical beneficiation

Physical beneficiation is a method of separating useful minerals and impurities in ore using physical properties. The physical beneficiation of titanium sand ore mainly includes gravity separation, magnetic separation, and electric separation.

1. Reselection

Gravity separation is a method of separation by using the density difference of minerals. The common useful minerals in titanium placer ores are Rutile, Ilmenite, etc., with high density, while impurities such as quartz, Galena, etc. have low density. Therefore, useful minerals can be separated from impurities through re selection.

The steps for reselection are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Put the ore into the gravity separator and add water for stirring to fully mix the ore with water.

(3) Open the water inlet valve of the gravity separator to allow water to flow into the machine and suspend the ore in the water.

(4) Adjust the water flow speed and inclination of the gravity separator to make the ore settle down according to the density difference and separate useful minerals and impurities.

(4) Adjust the water flow speed and inclination of the gravity separator to make the ore settle down according to the density difference and separate useful minerals and impurities.

2. Magnetic separation

Magnetic separation is a method of separating minerals by utilizing their magnetic differences. Ilmenite in ilmenite placer has strong magnetism, while impurities such as quartz and Galena have no magnetism. Therefore, useful minerals can be separated from impurities through magnetic separation.

The operating steps for magnetic separation are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Put the ore into the magnetic separator, add water for stirring, and fully mix the ore with water.

(2) Put the ore into the magnetic separator, add water for stirring, and fully mix the ore with water.

(3) Open the water inlet valve of the magnetic separator to allow water to flow into the separator and suspend the ore in the water.

(4) Activate the magnetic field of the magnetic separator to magnetize useful minerals, which are then adsorbed by the magnetic force of the separator to separate useful minerals and impurities.

3. Electric selection

Electric separation is a method of separating minerals by utilizing their differences in conductivity. Ilmenite in ilmenite placer has strong conductivity, while impurities such as quartz and Galena have poor conductivity. Therefore, useful minerals can be separated from impurities through electrical separation.

The operation steps of electric selection are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Put the ore into the electric separator and add water for stirring to fully mix the ore with water.

(3) Open the water inlet valve of the electric separator to allow water to flow into the separator and suspend the ore in the water.

(3) Open the water inlet valve of the electric separator to allow water to flow into the separator and suspend the ore in the water.

(4) Electrochemical treatment of the ore is carried out through electrodes, enabling useful minerals to be electrochemically adsorbed and separating useful minerals and impurities.

2、 Chemical beneficiation

Chemical beneficiation is a method of separating useful minerals from impurities in minerals using chemical reactions. The chemical beneficiation of titanium sand ore mainly includes two methods: flotation and leaching.

1. Flotation

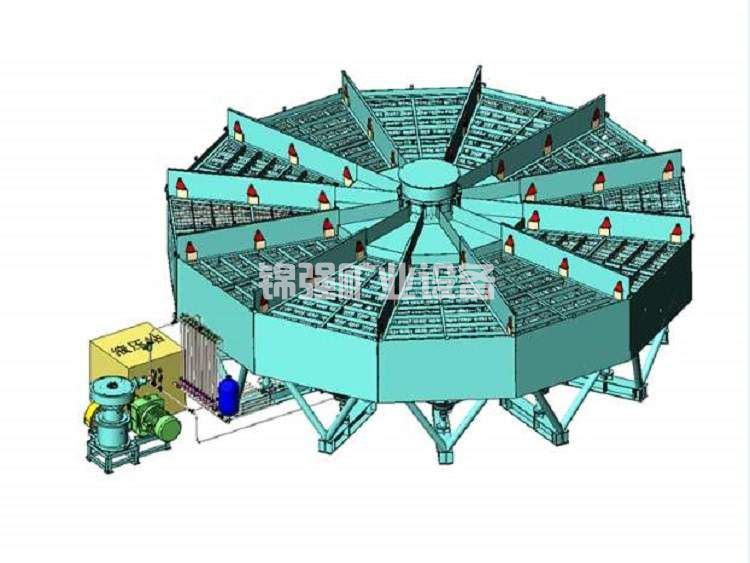

Flotation is a method of using chemical agents to float useful minerals and then separate them from impurities. The flotation of titanium placer is mainly to use hydrofluoric acid to flotation Ilmenite.

The operation steps of flotation are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Put the ore into the flotation cell, add hydrofluoric acid and foam agent for stirring, so that the ore and agent are fully mixed.

(3) Open the water inlet valve of the flotation cell to allow water flow to enter the flotation cell and suspend the ore in the water.

(3) Open the water inlet valve of the flotation cell to allow water flow to enter the flotation cell and suspend the ore in the water.

(4) Useful minerals are floated up through bubbles and then separated from impurities.

2. Leaching

Leaching is a method of using chemical agents to dissolve useful minerals from ores and then separate them from impurities. The leaching of titanium placer ore is mainly to use sulfuric acid to leach Ilmenite.

The steps for leaching are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Put the ore into the leaching tank, add sulfuric acid for stirring, and fully mix the ore with the reagent.

(3) Heat the leaching tank to react sulfuric acid with the ore and dissolve useful minerals from the ore.

(4) Separate useful minerals from impurities through filtration or precipitation.

3、 Comprehensive beneficiation

Comprehensive beneficiation is a method that combines physical beneficiation with chemical beneficiation. The comprehensive beneficiation of titanium sand ore mainly utilizes a combination of physical and chemical beneficiation methods, such as gravity flotation, magnetic separation flotation, and electrical separation flotation.

The operational steps for comprehensive beneficiation are as follows:

(1) Crush titanium sand ore into appropriate particle size, usually 0.5-1mm.

(2) Physical beneficiation of ore, such as gravity separation, magnetic separation, electric separation, etc.

(3) Chemical beneficiation of the ore after physical beneficiation, such as flotation, leaching, etc.

(4) Separate useful minerals from impurities through filtration or precipitation.

summary

The beneficiation methods of titanium sand ore mainly include physical beneficiation, chemical beneficiation, and comprehensive beneficiation.