Tin tungsten ore is an important metal ore with high tin and tungsten content, making it widely used in smelting and manufacturing. In order to improve the grade and recovery rate of tin tungsten ore, gravity beneficiation is a commonly used ore beneficiation method. This article will introduce the process flow and operational steps of gravity beneficiation of tin tungsten ore.

1、 Gravity beneficiation process flow of tin tungsten ore

The gravity beneficiation process of tin tungsten ore mainly includes four stages: coarse beneficiation, intermediate beneficiation, selection, and tail beneficiation. The specific process is as follows:

1. Rough selection stage

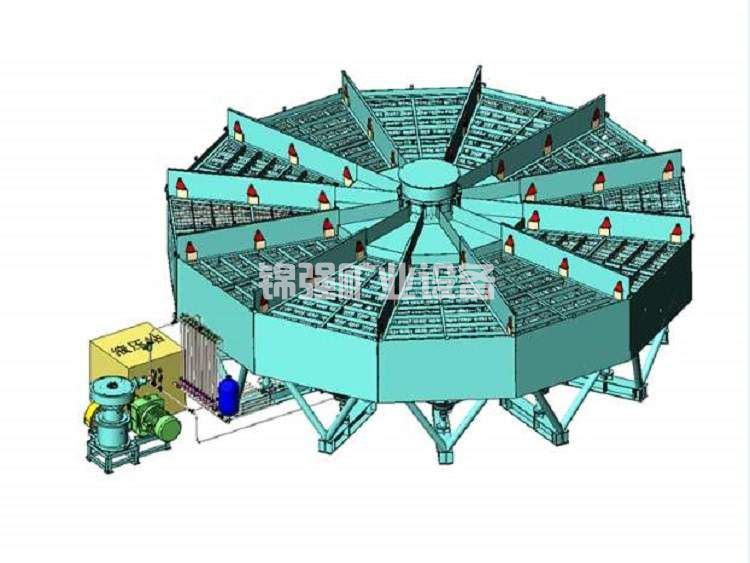

The rough selection stage mainly involves preliminary separation through a gravity concentrator. Firstly, the raw ore is processed through crushing, grinding and other processes, and then preliminary separation is carried out through a gravity concentrator. The beneficiation principle of the concentrator is to separate minerals through their density differences. Therefore, some beneficiation agents need to be added in the rough separation stage to increase the density differences of minerals, so as to improve the beneficiation effect. After rough selection, tin tungsten concentrate and tailings can be obtained.

2. Selected stage

2. Selected stage

The intermediate stage mainly involves further separation of the tin tungsten concentrate after rough selection. At this stage, equipment such as gravity concentrators and flotation machines need to be used for separation. Unlike the roughing stage, the intermediate stage does not require the addition of beneficiation agents, but is separated through different beneficiation principles of the equipment. After being selected, higher grade tin tungsten concentrate and tailings can be obtained.

3. Selection stage

The concentration stage is the Key Stage of gravity beneficiation of tin tungsten ores. At this stage, equipment such as gravity concentrators, flotation machines, and magnetic separators need to be used for separation. The purpose of the selection stage is to further remove impurities from the tin tungsten concentrate and improve the grade. After selection, higher grade tin tungsten concentrate and tailings can be obtained.

4. Final selection stage

4. Final selection stage

The final stage of gravity beneficiation of tin tungsten ore is the final stage. At this stage, equipment such as flotation machines and magnetic separators need to be used for separation. The purpose of tail selection is to further remove impurities from the selected tin tungsten concentrate and improve its grade. After tailings selection, the final tin tungsten concentrate and tailings can be obtained.

2、 Operating Steps

The operational steps for gravity beneficiation of tin tungsten ore are as follows:

1. Crush and grind the raw ore through various processes.

2. Add beneficiation agents during the rough selection stage and perform preliminary separation through a gravity concentrator.

2. Add beneficiation agents during the rough selection stage and perform preliminary separation through a gravity concentrator.

3. During the intermediate stage, gravity concentrators, flotation machines, and other equipment are used for separation.

4. During the selection stage, gravity concentrators, flotation machines, magnetic separators, and other equipment are used for separation.

5. Use flotation machines, magnetic separators, and other equipment for separation during the tail selection stage.

6. Dry and package the separated tin tungsten concentrate.

3、 Summary

Gravity beneficiation of tin tungsten ore is a commonly used ore beneficiation method that can effectively improve the grade and recovery rate of tin tungsten ore. The gravity beneficiation process of tin tungsten ore mainly includes four stages: rough selection, intermediate selection, selection, and tail selection, each stage requiring the use of different equipment for separation. During the operation process, attention should be paid to adding mineral processing agents and controlling the operating parameters of the equipment.