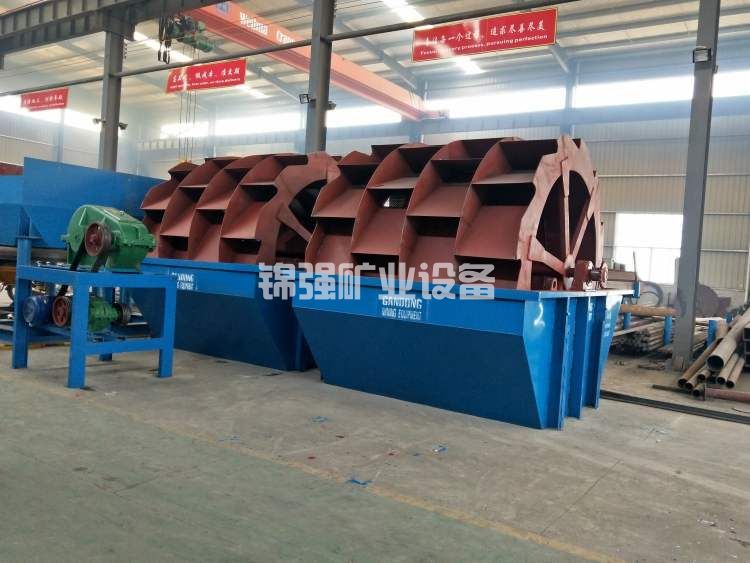

The crushing production line (stone crushing production line) equipment is a professional stone equipment for producing and manufacturing sand and gravel materials for construction, including jaw crusher, stone crusher, impact crusher, impact crusher, feeder, vibrating screen, sand washing machine, belt conveyor, etc. The equipment of the stone crushing production line has reliable characteristics, effective design schemes, convenient practical operation, and high work efficiency.

Equipment characteristics of stone crushing production line

1. The equipment of the sand and gravel crushing production line has a high level of automation technology, high crushing ratio, high production efficiency, and large output. The products that have undergone crushing are cubic in shape, with low needle block composition, no internal gaps, and high tensile strength.

2. The sand and gravel crushing production line equipment is easy to maintain and repair, and the spare parts are made of new high-strength metal composite materials from China, with low consumption and long service life, which can generate rich economic benefits for customers.

The sand and stone crushing production line equipment designed has been successfully applied in the crushing production and processing of rock layers such as dolomite, basalt, granite, and river pebbles. The quality of the crushed products completely meets the GB14685-2001 standard. The sand and stone crushing production line has provided qualified stone materials for high roads, railway lines, water conservancy projects, concrete mixing stations, and other fields.

Process Flow of Sand and Stone Crusher Production Line

The steps of the sand and gravel crusher production line are roughly as follows: (hopper) - vibrating feeder - jaw crusher - impact crusher - vibrating screen - (can be made into finished products). The equipment in the middle can be connected by a belt conveyor.

At first, the sand and stone materials are evenly sent to the coarse crusher by the vibrating feeder for basic crushing. Then, the produced coarse feed is transported by the belt conveyor to the impact crusher for further crushing. The crushed sand and stone materials are sent to the vibrating screen to select the crushed stones of different specifications and models. The returned crushed stones that do not meet the particle size distribution regulations are sent to the impact crusher for further crushing.

Equipment characteristics of sand and gravel crusher production line

This gravel crusher production line has a high level of automation technology, adjustable size of blanking particle size distribution, high bulk density, environmental protection and energy saving, and large production capacity. The produced gravel particles have a uniform Degree distribution, good particle shape, and are suitable for various large, medium and small construction projects such as roads, roads and bridges.

The equipment of the sand and gravel crushing production line mainly relies on the impact effect to crush raw materials. The entire process of crushing is roughly like that. The raw materials enter the crusher and are crushed by the impact of the rapidly rotating drill bit. The crushed raw materials obtain mechanical energy from the drill bit and run quickly towards the frame partition and screen strip. In addition, the raw materials collide with each other and suffer multiple crushing. The raw materials below the gap of the screen strip are discharged from the gap, and some large raw materials pass through the impact of the drill bit again on the screen strip, Grinding, extrusion, and crushing, where raw materials are squeezed from the gaps by the drill bit. And then obtain the commodity with the required particle size distribution.