Zircon is an important mineral resource widely used in industries such as ceramics, glass, and building materials. Gravity beneficiation process is a commonly used method in the mining process of zircon. This article will introduce the gravity beneficiation process flow and operating steps of zircon.

1、 Gravity beneficiation process flow of zircon

The gravity beneficiation process of zircon mainly includes four steps: rough selection, intermediate selection, selection, and tailings treatment.

1. Rough selection

Rough selection is the first step in the gravity beneficiation process of zircon, with the aim of removing most of the waste and impurities in the ore to obtain a relatively pure zircon rough selection product. The rough selection mainly adopts the heavy medium separation method, which mixes the ore with the heavy medium and separates the waste rock and impurities through the buoyancy difference of the medium.

2. Successful selection

The intermediate selection is the second step of the gravity beneficiation process for zircon, with the aim of further improving the grade and recovery rate of zircon. The medium selection mainly adopts the heavy liquid separation method, which mixes the coarse selected product with the heavy liquid and separates the zircon and waste stone through the buoyancy difference of the heavy liquid.

3. Selection

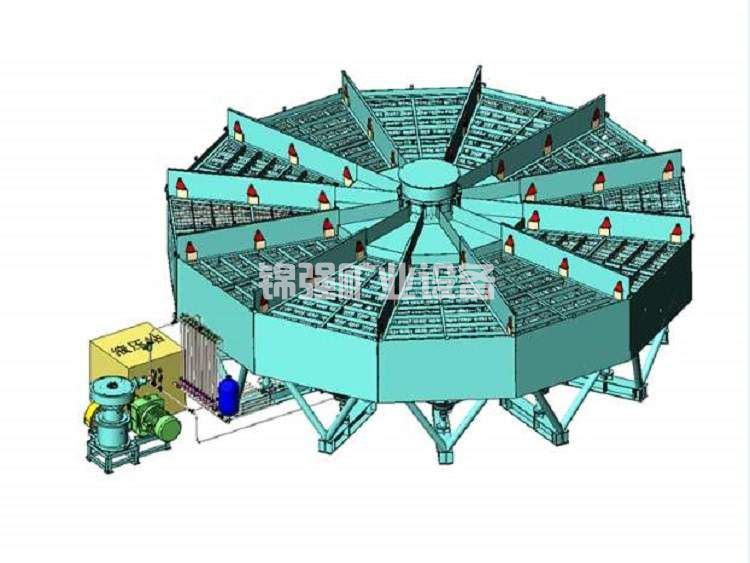

Selection is the third step of the gravity beneficiation process for zircon, with the aim of further purifying the zircon in the selected product to obtain high-quality zircon concentrate. The selection mainly adopts the gravity separation method, which separates the selected products from the vibration table or inclined plate sorting machine for gravity separation, and separates the zircon and waste stones.

4. Tailings treatment

Tailings treatment is the final step of the zircon gravity beneficiation process, with the aim of treating the waste residue generated during the beneficiation process to meet environmental requirements. The tailings treatment mainly adopts flotation or magnetic separation methods to further recycle and utilize useful minerals in the waste residue, while removing harmful substances from the waste residue.

2、 Operating steps of zircon gravity beneficiation process

1. Steps for rough selection

(1) Crush the ore to the appropriate size.

(2) Mix the ore with the heavy medium and adjust the density and concentration of the heavy medium.

(3) Place the mixture into a heavy medium separator and separate the waste rock and impurities through buoyancy differences.

(4) Collect the separated zircon rough selection.

2. Selection steps

(1) Mix the rough selection of zircon with the heavy liquid and adjust the density and concentration of the heavy liquid.

(2) Place the mixture into a heavy liquid separator and separate zircon and waste stones through the buoyancy difference of the heavy liquid.

(3) Collect the selected zircon from the separated zircon.

3. Selected operation steps

(1) Gravity sorting is performed on the selected zircon using a vibrating table or inclined plate sorting machine.

(2) Adjust the vibration frequency and amplitude of the sorting machine to separate zircon and waste stone.

(3) Collect the separated zircon concentrate.

4. Operation steps for tailings treatment

(1) Treat the waste generated during the beneficiation process to remove harmful substances.

(2) Use flotation or magnetic separation methods to further recover and utilize useful minerals in the waste residue.

(2) Use flotation or magnetic separation methods to further recover and utilize useful minerals in the waste residue.

3、 Summary

The gravity beneficiation process of zircon ore includes four steps: rough selection, intermediate selection, selection, and tailings treatment, each step having its own specific operating steps. In actual production, reasonable process design and operational control should be carried out based on the characteristics and process requirements of the ore, in order to improve the grade and recovery rate of zircon, reduce production costs, and protect the environment.