Chromite spiral chute 1. Explain that gravity concentration spiral chute is a combination of glass fiber reinforced plastic spiral chute, gravity beneficiation spiral chute, shaking table, centrifugal concentrator. After relevant scientific research organized by the Ministry of Metallurgy, and the operation appraisal of the design, school, concentrator and other departments, it is recognized that the machine has excellent performance and advanced sorting goals. At the same time, it has won the scientific and technological research achievement award from the Ministry of Metallurgy Industry. Now it has been in the non-ferrous Ferrous mines are widely used. This machine is suitable for sorting iron, ferrotitanium, ferrochrome, pyrite, zircon sand, Rutile, monazite, phosphate rock, tungsten ore, tin ore, tantalum ore, tantalum niobium and other nonferrous metal, rare metal and nonferrous metal ore bodies with different specific gravity. 2、 The mortar with the same working principle is slowly fed onto the surface of the spiral groove through the feeding chute installed at the end of the rotating groove head, and selected for operation. The tail of the rotating groove is equipped with a valve block type product cutting groove, which divides the sorting equipment into three categories according to grade along the radial direction. By adjusting the position of the valve block to change the acquisition width of each product, the equipment gathering hopper enables the selected multi head ore flow to converge and export separately. The cross-section of the spiral chute and the slope of the curve change greatly, which is applied to the selection of fine ore materials. Chromite spiral chute  III. Features 1. Stable separation process and easy control 2. Large allowable range of ore feeding density 3. Super high enrichment ratio and high recovery probability 4. Small area occupied and low water consumption 5. Simple structure without power 6. Strong processing capacity 7. Simple installation and simple operation 8. Small input and quick results

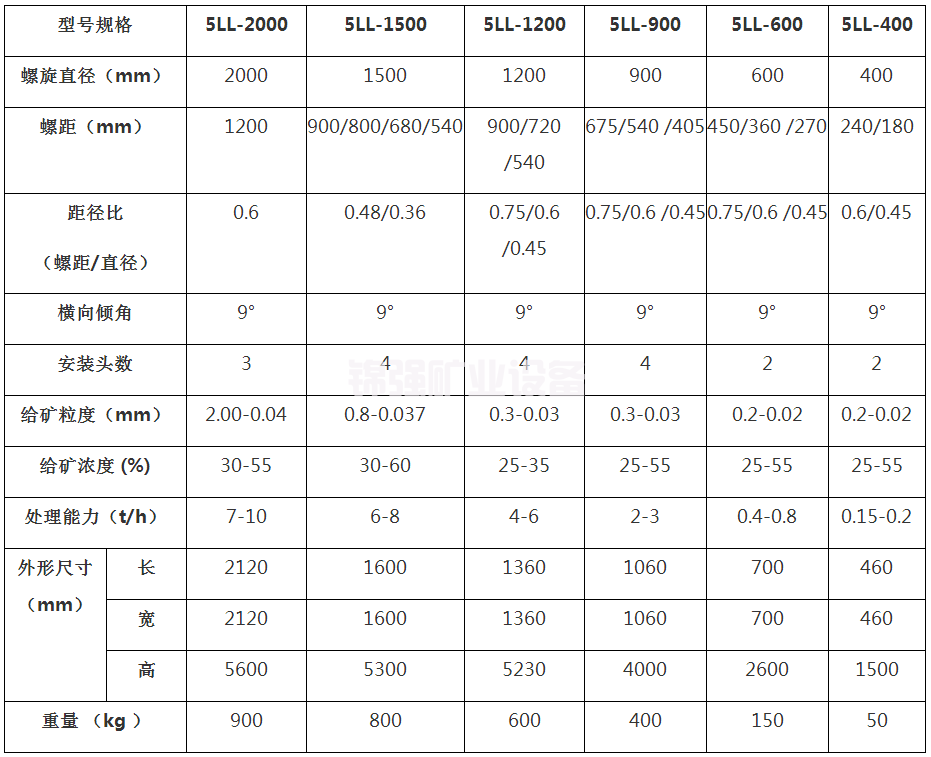

III. Features 1. Stable separation process and easy control 2. Large allowable range of ore feeding density 3. Super high enrichment ratio and high recovery probability 4. Small area occupied and low water consumption 5. Simple structure without power 6. Strong processing capacity 7. Simple installation and simple operation 8. Small input and quick results  Chromite spiral chute 4. Classification according to the size of ore processed, Chutes can be divided into three categories: (1) coarse spiral chute, the maximum Granularity of ore feeding is more than 2-3MM, and the maximum can reach 100-200mm. (2) The sand ore chute is used to handle 2-3mm sized ore materials. (3) Slurry chute, feeding particle size less than 0.074 millimeters. Chromite spiral chute V. This equipment is applicable to the separation of fine and small materials with a Granularity of 0.3-0.02mm to obtain iron ore, Ilmenite, Chromite, pyrite, zircon, Rutile, monazite, phosphorus ethylene, tungsten, tin ore, tantalite, tantalum niobium ore or other non-ferrous metal, rare metal and non-ferrous metal ore bodies with different density and specific gravity.

Chromite spiral chute 4. Classification according to the size of ore processed, Chutes can be divided into three categories: (1) coarse spiral chute, the maximum Granularity of ore feeding is more than 2-3MM, and the maximum can reach 100-200mm. (2) The sand ore chute is used to handle 2-3mm sized ore materials. (3) Slurry chute, feeding particle size less than 0.074 millimeters. Chromite spiral chute V. This equipment is applicable to the separation of fine and small materials with a Granularity of 0.3-0.02mm to obtain iron ore, Ilmenite, Chromite, pyrite, zircon, Rutile, monazite, phosphorus ethylene, tungsten, tin ore, tantalite, tantalum niobium ore or other non-ferrous metal, rare metal and non-ferrous metal ore bodies with different density and specific gravity.  Chromite spiral chute

Chromite spiral chute

- Home

- About us

Enterprise Introduction development history Honorary qualifications Technical research and development

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents.

Ganzhou Jinqiang Mining Equipment is a large-scale mining service company specializing in mining machinery manufacturing, mineral analysis, beneficiation process design, equipment selection, and equipment installation and debugging. The company has two large production bases, covering an area of 50000 square meters, with a workshop area of over 20000 square meters. We have 15 years of experience in manufacturing beneficiation equipment. The company's products have all passed ISO9001 and GOST international quality system certification. The gravity beneficiation equipment produced by the company, such as ore dressing shakers, jigs, and spiral chutes, is exported to more than 50 countries worldwide, with customers spread across all continents. - device

Shaker beneficiation equipment Spiral Chute equipment Jig equipment Concentrator equipment Magnetic separator equipment Flotation machine equipment Crusher equipment ball mill Vibrating screen equipment Roller screen equipment Classifier equipment Ore washing machine Sand making machine equipment Sand washing machine equipment

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity beneficiation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. - programme

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China.

The company has a variety of large-scale modern machining equipment, professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation team. The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Our company's gravity separation equipment such as ore dressing shakers, jigs, and spiral chutes account for 15% of the market share of gravity separation equipment in China. - news

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China.

The company's core business is gravity separation equipment, magnetic separation equipment, ore washing equipment, screening equipment, crushing and grinding equipment, flotation equipment, and mineral conveying equipment. Production of mineral processing equipment, sand gold processing equipment, gold ore processing equipment and Hematite processing equipment and other mineral processing equipment. Our company's gravity beneficiation equipment such as shakers, jigs, and spiral chutes account for 15% of the market share of gravity beneficiation equipment in China. - contact us

- Home

- About us

- device

- Shaker beneficiation equipment

- Spiral Chute equipment

- Jig equipment

- Concentrator equipment

- Magnetic separator equipment

- Flotation machine equipment

- Crusher equipment

- ball mill

- Vibrating screen equipment

- Roller screen equipment

- Classifier equipment

- Ore washing machine

- Sand making machine equipment

- Sand washing machine equipment

- programme

- news