Titanium zirconium ore is an important metal mineral resource, which mainly includes titanium ore and zirconium ore. In the beneficiation process of titanium zirconium ore, the use of gravity beneficiation process is a common method. This article will introduce the titanium zirconium gravity beneficiation process flow, helping readers understand the operating steps and precautions of this process.

1、 Process flow

The titanium zirconium gravity beneficiation process mainly includes ore crushing, grinding, gravity separation, selection, and tailings treatment.

1. Ore crushing

Titanium zirconium ore needs to be crushed after transportation in the mine. Generally, equipment such as jaw crushers, cone crushers, or impact crushers are used for crushing. After ore crushing, the particle size is generally below 50mm.

2. Grinding

After ore crushing, grinding treatment is required. The purpose of grinding is to refine the ore and improve beneficiation efficiency. Commonly used grinding equipment includes ball mills, rod mills, etc. After grinding, the particle size of the ore is generally below 0.074mm.

3. Reselection

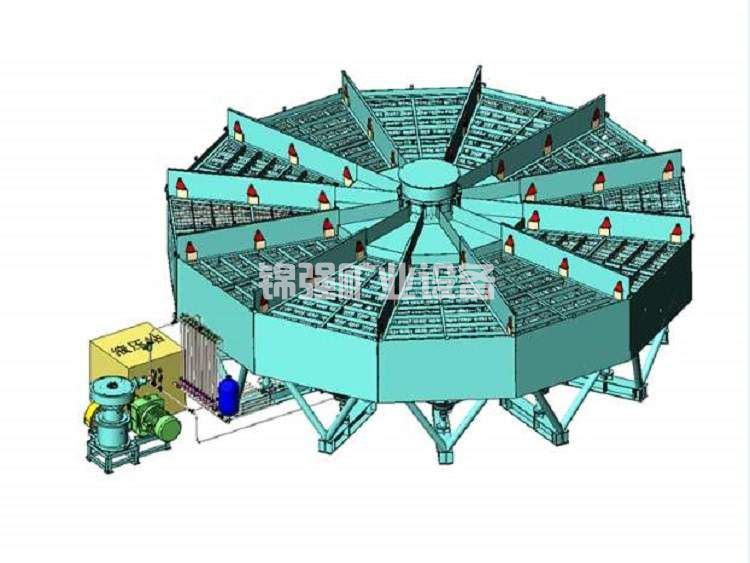

Gravity beneficiation is the core process of titanium zirconium ore gravity beneficiation. During the gravity separation process, equipment such as heavy medium sorting machines, spiral sorting machines, and centrifugal sorting machines are used for sorting. After gravity separation, titanium ore and zirconium ore are separated to achieve the purpose of beneficiation.

4. Selection

purification is the further purification of titanium zirconium ore after gravity separation. Selection is generally carried out using equipment such as high-strength magnetic separators and electrostatic separators. After selection, the purity of titanium ore and zirconium ore is further improved.

5. Tailings treatment

Tailings treatment is the final step in the titanium zirconium gravity beneficiation process. In tailings treatment, equipment such as pressure filters and dewatering screens are used to treat tailings, removing moisture and impurities from the tailings and meeting environmental requirements.

2、 Precautions

In the titanium zirconium gravity beneficiation process, the following points need to be noted:

1. The selection of equipment for ore crushing and grinding should be based on the ore properties and particle size requirements.

During the process of gravity separation, the selection of heavy media should be based on the ore density and sorting effect.

During the selection process, the selection of magnetic field strength and electrostatic field strength should be based on the ore properties and sorting effect.

During the tailings treatment process, it is necessary to pay attention to environmental requirements and minimize the discharge of wastewater and waste residue as much as possible.

III. Conclusion

III. Conclusion

The titanium zirconium gravity beneficiation process is a common beneficiation method with the advantages of simple operation and low cost. In actual production, selection and adjustment should be made based on ore properties and beneficiation requirements to achieve the best beneficiation effect.