Tin tungsten ore is an important metal ore widely used in fields such as metallurgy, electronics, aviation, and aerospace. The mining and beneficiation of tin tungsten ore is a complex process that requires a series of separation and beneficiation processes. This article will introduce the process flow chart and operating steps of tin tungsten ore separation and beneficiation.

1、 Process flow diagram of separation and beneficiation of tin tungsten ore

The process flow diagram of separation and beneficiation of  tin tungsten ore is as follows:

tin tungsten ore is as follows:

1. Rough selection: Use a jaw crusher to break the ore into small pieces, and then use a cone crusher to break it into smaller particles. Next, use a ball mill to refine the particles to a certain degree of fineness.

2. Intermediate selection: A flotation machine is used for intermediate selection to separate useful minerals from waste rock in the ore. In the flotation machine, chemicals are added to combine useful minerals with bubbles, thereby floating up to the surface of the flotation machine and forming scum. The waste rock sinks to the bottom, forming tailings.

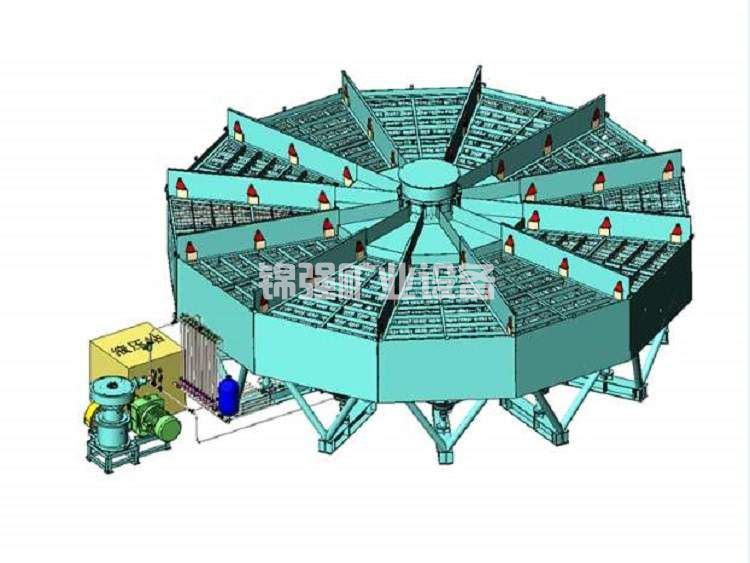

3. Selection: A gravity separator is used for selection, separating the scum in the flotation machine again to obtain high-purity useful minerals. The gravity separator separates according to the density difference of ores, so that useful minerals can be effectively separated from waste rocks.

4. Tailings treatment: For the tailings in the gravity separator, tailings treatment equipment is used for treatment. Tailings processing equipment can recover useful minerals from tailings, thereby improving the comprehensive utilization rate of the ore.

4. Tailings treatment: For the tailings in the gravity separator, tailings treatment equipment is used for treatment. Tailings processing equipment can recover useful minerals from tailings, thereby improving the comprehensive utilization rate of the ore.

2、 Operation steps of separation and beneficiation process flowchart for tin tungsten ore

1. Steps for rough selection:

(1) Feed the tin tungsten ore into a jaw crusher for preliminary crushing.

(2) Send the preliminarily crushed ore into a cone crusher for secondary crushing.

(3) Send the ore after secondary crushing into a ball mill for refining treatment.

2. Selection steps:

(1) Feed the refined ore into the flotation machine.

(2) Add chemicals to combine useful minerals with bubbles, thereby floating to the surface of the flotation machine and forming scum.

(3) The waste rock sinks to the bottom, forming tailings.

3. Selected operation steps:

(1) Feed the scum from the flotation machine into the gravity separator.

(2) The gravity separator separates according to the density difference of ores, so that useful minerals can be effectively separated from waste rocks.

4. Steps for tailings treatment:

(1) Feed the tailings from the gravity separator into the tailings treatment equipment for treatment.

(2) Tailings processing equipment can recover useful minerals from tailings, thereby improving the comprehensive utilization rate of the ore.

3、 Conclusion

The separation and beneficiation process flowchart of tin tungsten ore is a complex process that requires a series of separation and beneficiation processes. By operating steps such as rough selection, intermediate selection, selection, and tailings treatment, useful minerals and waste rocks in tin tungsten ore can be effectively separated, thereby obtaining high-purity useful minerals. In practical applications, it is necessary to select appropriate process flows based on the characteristics of the ore and production needs to achieve the best separation effect.