Tungsten tin tailings are a valuable ore, but their recovery and utilization rate is very low due to their complex mineral composition and difficulty in separation. In order to improve the recovery and utilization rate of tungsten tin tailings, many researchers have conducted extensive research and ultimately developed a new recycling and beneficiation technology. This article will introduce the operational steps and application prospects of this new technology.

1. Operating Steps for New Technologies

1. Operating Steps for New Technologies

1. Raw material processing

1. Raw material processing

Firstly, it is necessary to process raw materials for tungsten tin tailings. Raw material processing includes steps such as ore grinding, desliming, and dehydration. The purpose of these steps is to remove impurities from the ore and make it more pure.

2. Mineral separation

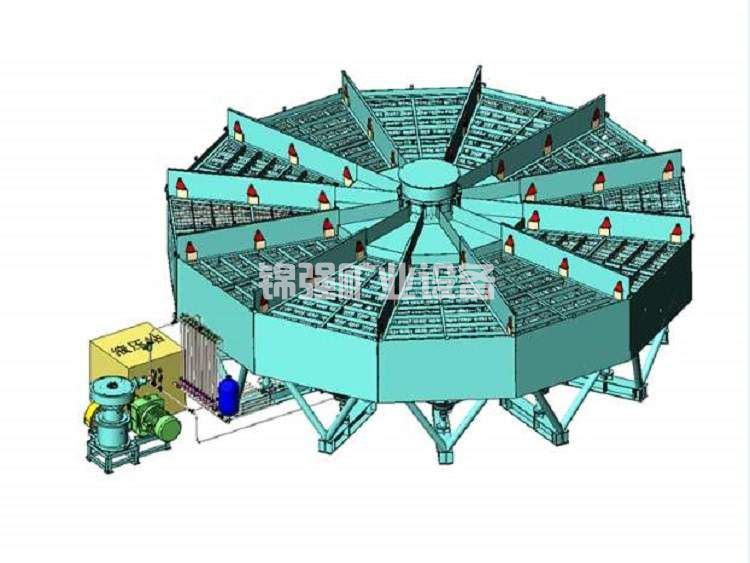

Next, mineral separation of the ore is required. This process includes steps such as gravity separation, flotation, and magnetic separation. The purpose of these steps is to separate tungsten minerals and tin minerals from tungsten tin tailings for subsequent processing.

3. Chemical treatment

After mineral separation, the obtained tungsten and tin minerals require chemical treatment. This process includes steps such as leaching, extraction, and precipitation. The purpose of these steps is to extract metal elements from tungsten and tin minerals for subsequent utilization.

4. Product preparation

Finally, it is necessary to prepare the extracted metal elements for product preparation. This process includes steps such as alloy preparation and powder metallurgy. The purpose of these steps is to prepare the extracted metal elements into practical materials for subsequent applications.

2、 The application prospects of new technologies

The application prospects of new technologies are very broad. Firstly, it can improve the recycling rate of tungsten tin tailings and reduce the consumption of natural resources. Secondly, it can improve the purity and quality of tungsten tin materials, and enhance their application value in industrial production. Finally, it can promote the sustainable development of the tungsten tin industry and contribute to the socio-economic development.

3、 Conclusion

The research and application of new technologies for tungsten tin tailings recovery and beneficiation is a hot topic in the current mining field. Through the introduction of the operation steps and application prospects of the new technology, we can see that this new technology has broad application prospects and is expected to become an important means for the sustainable development of the tungsten tin industry.