Zircon sand is an important industrial raw material, widely used in fields such as ceramics, glass, electronics, etc. Due to the special properties of zircon sand, it requires precise processing to meet the requirements. Zircon sand gravity separation equipment is one of the important equipment for achieving zircon sand processing. This article will introduce the operating steps and precautions of the zircon sand gravity separation equipment.

1、 Principle of Zircon Sand Gravity Separation Equipment

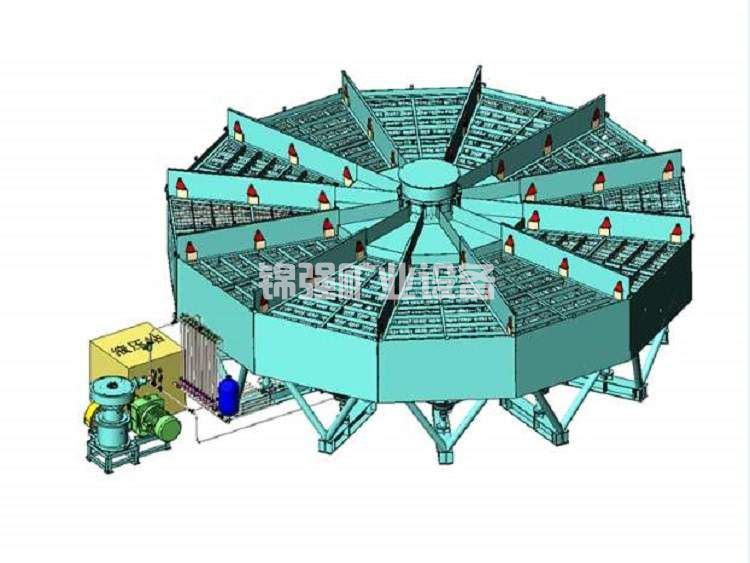

Zircon sand gravity separation equipment is a type of gravity beneficiation equipment that utilizes the differences in specific gravity of different minerals to separate them through hydraulic classification. The zircon sand gravity separation equipment mainly consists of a feeding trough, a rotating shaft, a sorting barrel, a base, and other parts. The feed chute evenly distributes the ore into the sorting bucket, which is driven by a rotating shaft for sorting. During the sorting process, heavy minerals will precipitate to the bottom, while light minerals will be separated, ultimately achieving the purpose of sorting.

2、 Operating Steps of Zircon Sand Gravity Separation Equipment

1. Preparation work

1. Preparation work

Before using the zircon sand gravity separation equipment, preparation work is required. First, check whether the equipment operates normally, including whether the rotating shaft, sorting barrel, feed chute and other parts are damaged or loose. Secondly, clean up the debris and residue inside the equipment to ensure its cleanliness and hygiene.

2. Adjust equipment parameters

Adjust the parameters of the zircon sand gravity separation equipment based on the properties and requirements of the ore. Mainly including parameters such as rotational speed, water flow rate, and feed rate. Generally speaking, the faster the rotation speed, the better the sorting effect, but excessive rotation speed can cause equipment damage. The water flow rate and feed rate need to be determined based on the properties of the ore and the capacity of the equipment.

3. Start sorting

Distribute the ore evenly into the feed chute and start the zircon sand gravity separation equipment. During the sorting process, it is necessary to gradually adjust the parameters according to the operation of the equipment to ensure that the sorting effect meets the requirements. At the same time, it is necessary to pay attention to the operation of the equipment, promptly handle abnormal situations, and avoid equipment damage or accidents.

4. Closing work

After using the zircon sand gravity separation equipment, the final work needs to be carried out. Firstly, turn off the device power and disconnect the power cord. Secondly, clean up any residues and debris inside the equipment to ensure its cleanliness and hygiene. Finally, inspect and maintain the equipment to ensure its normal operation.

3、 Precautions for Zircon Sand Gravity Separation Equipment

1. Before operating the equipment, it is necessary to conduct inspections and maintenance to ensure its normal operation.

When adjusting equipment parameters, it is necessary to make reasonable parameter adjustments based on the properties and requirements of the ore.

When using zircon sand gravity separation equipment, it is necessary to pay attention to the operation of the equipment, promptly handle abnormal situations, and avoid equipment damage or accidents.

4. During the final work, it is necessary to inspect and maintain the equipment to ensure its normal operation.

In short, the zircon sand gravity separation equipment is one of the important equipment for achieving zircon sand processing. When using zircon sand gravity separation equipment, it is necessary to pay attention to the operating steps and precautions to ensure the normal operation and sorting effect of the equipment.