The 6-S shaker is one of the key mechanical equipment for gravity beneficiation, and it is widely used in the separation of tungsten, tin, tantalum, niobium, gold and other non-ferrous and precious metal ores. It can be used for different work such as coarse selection, optimization and sweeping, and can be used to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm), mineral mud (-0.074), etc. with different particle size distribution. It can also be used to separate iron, manganese ore, and coal. When solving the problem of tungsten, tin and other iron ores, the reasonable purchase particle size distribution range of the shaker is 2-0.22mm.

The whole process of the beneficiation plant of the shaker is carried out on the surface of a slanted bed with multiple strips. The ore particles are fed from the ore feeding trough at the surface angle of the shaker, and at the same time, the transverse cleaning water is supplied to the stainless steel water tank. Therefore, the ore particles are divided into different levels according to proportion and particle size distribution under the effect of the inertial force and sliding friction caused by the force, the transverse water impact force, and the reciprocating fitness exercise of the shaker bed, And perform vertical fitness exercises along the rocking bed and horizontal fitness exercises along the tilted bed. Therefore, ore particles with different proportion and particle size distribution slowly flow down from side A to side B in fan shape along their respective fitness orientation, and are discharged from different areas at the titanium concentrate end and tailings pond side respectively, and then divided into titanium concentrate, middling and tailings pond.

The 6-s shaking table has a high silver ore ratio, high sorting efficiency, and is very easy to take care of, which is conducive to adjusting the four stroke. By changing the horizontal inclination and four stroke, the balanced operation of the shaker bed can still be maintained. The torsion spring is placed on the box body, with a compact structure, and the final titanium concentrate and tailings pond can be obtained successively.

6s shaking table structure and materials:

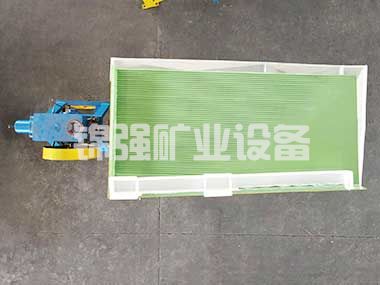

The key components of this 6s rocking bed include a bedroom bed, an electric motor, a slope adjuster, a bed body, a mining tank, a stainless steel sink, a strip and its air intake system.

The vertical repeated movement of the bed is completed based on a crank connecting rod transmission mechanism. According to the synchronous belt transmission, the motor drives the large belt pulley to push the engine crankshaft to rotate. The remote rod follows the up and down fitness movements, and when the remote rod moves down, the elbow plate promotes the rear wheel and reciprocating rod to move backwards, causing the torsion spring to shrink. The bed body is connected by a connecting seat and a reciprocating rod, so at this time, the bed body also undergoes a backward fitness exercise. When the remote rod moves up for fitness, the bed body moves forward due to the extension force of the torsion spring.

During the bed forward fitness exercise period, the intersection angle between the elbow plates changes from large to small, and the horizontal movement rate of the elbow plate nodes changes from small to large. Therefore, the forward fitness exercise of the bed body changes from slow to fast. On the contrary, when the rocking bed body reverses, it changes from fast to slow, leading to isometric fitness exercise. This ensures that the raw materials on the bed surface move forward and undergo proportional screening.

The external design of the shaking table body is a right angled trapezoid. In the wooden structure, the wooden board is inclined (45 degrees from the centerline) to make a plan. The bed body is divided into two types: painted gray grooved bed surface and vulcanized rubber bed body. The surface of the lacquer gray groove bed is used to select fine mud, while the vulcanized rubber bed body is used to select coarse ore. The surface of the shaker used for selecting fine mud is inclined vertically by 0.5 degrees, while the shaker used for selecting coarse sand is inclined vertically by 1-2 degrees and pulled up at the end of the titanium concentrate. The size of the vertical inclination is adjusted by the anchor bolts on the support point organization.

The bed is supported on the slope adjustment organization by shaking support points. Shake the support point to cause the bed to move repeatedly in front, back, left, and right of the oblique line around the vertical plan. The rocking support point is fixed on the adjustment seat plate with a steel rod. When the adjusting ball screw is used to rotate the adjustment seat plate on the saddle seat using the spindle, the inclination angle of the bed can be adjusted.

Application scope of 6s shaking table:

The 6-S shaker is one of the key mechanical equipment for gravity beneficiation, widely used in the separation of tungsten, tin, tantalum, niobium, gold and other non-ferrous and precious metal ores. It can be used for different work such as coarse selection, optimization and sweeping, and can be used to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm), mineral mud (-0.074), etc. with different particle size distribution. It can also be used to separate iron, manganese ore, and coal. When solving the problem of tungsten, tin and other iron ores, the reasonable purchase particle size distribution range of the shaker is 2-0.22mm.